Despite being an important technology since the 1980s, it has gained popularity recently. The technology came into the spotlight when people realized they could print almost any design at a much faster rate than printing through traditional methodologies. Hence large investments fuelled in the industry to make it more profitable. As a result, additive manufacturing technologies rapidly evolved, and today, we’re witnessing an explosion in their use, especially in metals.

In fact, the 3D printing revolution has been so heartening that almost all industry realms such as engineering, medical, jewellery, and mining are using 3D printing in some form or the other.

According to a survey by PwC, 11% of the 100 companies surveyed switched to 3D printing for mass production of their products. The technology will soon become a viable alternative to traditional printing methods.

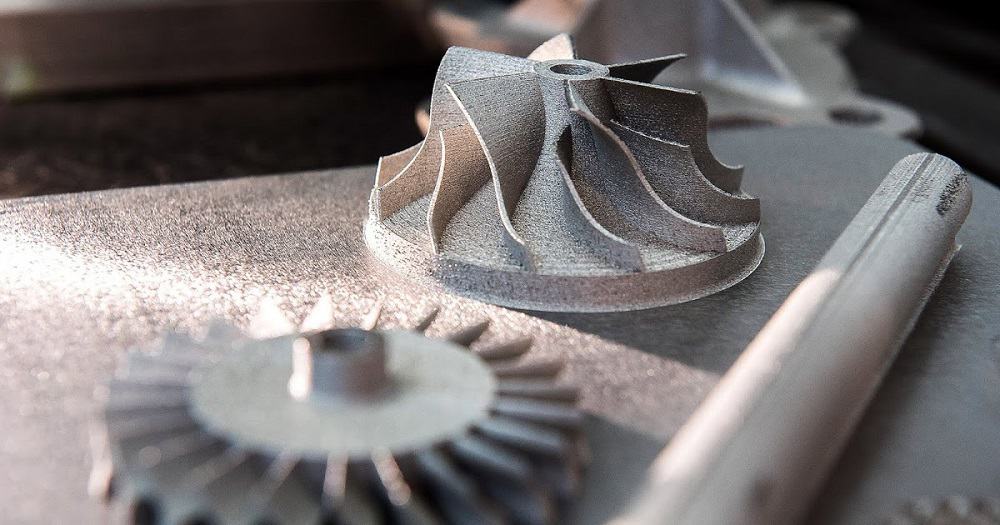

As the range of printing materials expands, most companies in the manufacturing space are using 3D printing in some manner or planning to use it. Along with using basic materials such as plastics and resins, one can use ceramics, glass, metals, and metal alloys as printing materials. But, just as this technology has so many advantages, it also raises questions and doubts.

At Zeal 3D printing, we are often asked whether metal 3D printing in Brisbane will outperform traditional methods? Whether purchasing a 3D printer is worth the bet? There’s no denying 3D printing holds much potential, but buying a 3D printer can be expensive and might not be useful. However, purchasing a 3D printer isn’t the only option; you can avail metal 3D printing services at a fraction of the cost.

Having said that, let see the key advantages of metal 3D printing over traditional methods

1. Reduction of Lead Times

The primary benefit of using metal printing is the fast transition of 3D printing from the design stage to the production. Because of instrumentation matter, a lot of time is saved. After the metal part is 3D printed, you don’t require many tools or machines to process it. One only needs to remove the support structures used in the printing. This significantly reduces the post-processing time. Plus, with metal 3D printing, you also don’t need to bring the part in the right shape using different traditional tools. Hence, this overall reduce the lead times to 2-3 days instead of weeks.

2. Low Waste

The traditional milling process, stamping, and producing large sheets of metal results in wastage of the raw material. On the other hand, Brisbane 3D printing melts only the powder or wire required to build the component’s structure layer by layer. Manufacturers can then remove the excess power or wire and reuse it. This not only helps in reducing the raw material but also makes the process less labour intensive.

3. Design Freedom

With 3D metal printing Brisbane, you can print almost any part, no matter how complex it is. It opens up a plethora of designing possibilities. 3D metal printing services equips you to get rid of all the design and manufacturing constraints. You want to develop a highly complex rib cage; you can easily do it with metal 3D printing. Metal printing Brisbane also reduces the amount of material used for a part and delivers the same functionality as the conventional 3D printing method.

4. Cost-Effective for Small-Scale Manufacturers

Today, most manufacturing happens on a large scale, which leaves small-scale manufacturers with only a handful of options. Let us say you produce hairpins. The average production batch of the product in conventional printing is 300 tons — a lot more than the annual demand. In such a scenario, a considerable amount of raw material will also be wasted. Hence, in such cases, metal 3D printing proves out to be a boon. Besides, you can avail services of an expert metal 3D printing service provider who will deliver bespoke 3D printed designs at cost-efficient rates in less lead time.

How Can One Work to Integrate 3D Printing in Their Business?

Companies must work towards incorporating 3D printing at three strategic levels —

- Product offerings

With the advent of metal 3D printing, companies now have to think about the features they can include, which were not possible earlier. How can you better serve your customers? What aspects of the product can be improved since the lead time is reduced?

- Operational Efficiency

The major benefit of using metal 3D printing is that enhances the overall operational efficiency. Companies need to ponder–how much they can save by cutting redundant steps? Or by changing their ways of selling? This way, manufacturers will have a clear idea about what they have to produce through additive manufacturing and in what quantity?

- Reconfigure ecosystems

Metal 3D printing has brought ample of new opportunities. With the help of 3D printing services, you can try several businesses. So, for example, you can manufacture medical equipment one day and toys the other day. You can experiment and find the one that’s suits you the best.

Taking Metal 3D Printing a Notch Up

We at Zeal 3D printing constantly strive to improve our technologies and make 3D printing accessible for everyone. With the same vision, we want businesses of all shapes and sizes to experience the disruptive metal 3D printing services that offer freedom of design, cost-effectiveness, and robustness of printed parts. We aim to make metal 3D printing everyone’s first choice, which is why we have opened a new office in Brisbane.

Want to consult us? You can call or chat with our metal 3D printing experts to discuss your goals. Together, we can design the best for your brand and take it to the next level.

Author’s Bio : The director of Zeal 3D Printing, Kiran H. is the author of this article. He is offering 3d printing services from past so many years. He has earned good success in the 3d printing industry as well as 3d scanning services for his unique and custom designs for his clients.